What We Do – Step Change Transformation

Your operation. Your people. Our support.

You’ve got an asset-intensive organization. You want to manage risk and improve productivity, reliability, and operational performance. We’ve got subject matter experts who have developed the work processes, tools and diagnostics to help your organization reach its goals. Not only that – we’ll engage, coach and educate your team, building your organizational capabilities.

LCE originated Maintenance Excellence® and Reliability Excellence® methodologies, and we’re now supporting clients in digital operations. We can help you identify, prioritize and address your operational goals, whether you need a targeted project like creating an asset hierarchy or want to complete a plant-wide transformation.

Asset Productivity Consulting Services

At our core, we’re dedicated to assisting clients in optimizing their operational assets. Whether you’re gearing up for a new venture or committed to enhancing an ongoing operation, our resources, systems, and work processes are all geared toward minimizing operational expenses while enhancing asset reliability and overall operational availability.

Improving asset productivity requires understanding where your current systems are underperforming, developing processes and capabilities to close performance gaps, and creating a culture that supports continuous improvement. Our experience helping hundreds of clients ranges from multi-site, organizational transformations to diagnosing and fixing a specific production line problem.

Strategic Alignment, Planning and Global Design Workshops

An executive alignment workshop designed to help prioritize improvement opportunities and develop a plan to achieve enterprise-wide step-change performance improvement.

What to Expect:

An executive workshop that:

- Quantifies opportunities based on industry performance benchmarking

- Develops shared understanding of current state performance

- Applies organizational change management best practices and enterprise reengineering best practices

- Develops a roadmap for the organization’s performance improvement

Outcomes:

An actionable strategic plan, including:

- A business case outlining current state, SWOT, reliability maturity and financial benefits of implementing an enterprise-wide continuous improvement program

- Defined alignment between client business objectives and program mission, vision and governing principles

- Integration points between current initiatives and step-change improvement program

- A program management plan with:

- Enterprise implementation strategy and plan

- Risk plan

- Change management strategy

Success Stories:

US Sugar Corporation Keeps the Train Moving With Reliability Excellence

Aluminum Smelter Improves Asset Reliability and Reinvigorates Operations with Reliability Excellence

Operational Readiness Consulting

Start a new capital project with operational excellence.

A program management system that incorporates construction, commissioning and operational readiness activities significantly improves your likelihood of success in meeting milestones and deadlines, preparing your workforce, and managing costs across the life cycle of your capital project.

What to Expect:

Our Operational Readiness experts can provide the following:

- Operational Risk Assessment: Identify risks from your project’s design phase through to steady-state operations – early enough to confirm strategy and implement cost-effective mitigation measures

- Integrated Master Schedule (IMS): Provide all project participants with a consistent tool for planning, executing and tracking activity

- Checkpoint Process: LCE’s checkpoint process provides a structured approach and roadmap to identify and remedy deficiencies and validate deliverables that need to be adequately prepared for project startup

Success Stories:

Steel Mill Mitigates Impact of Shutdowns With an Operational Risk Assessment and Risk Register

An Operational Readiness Audit Helps Supermarket Chain Expand Production on Schedule

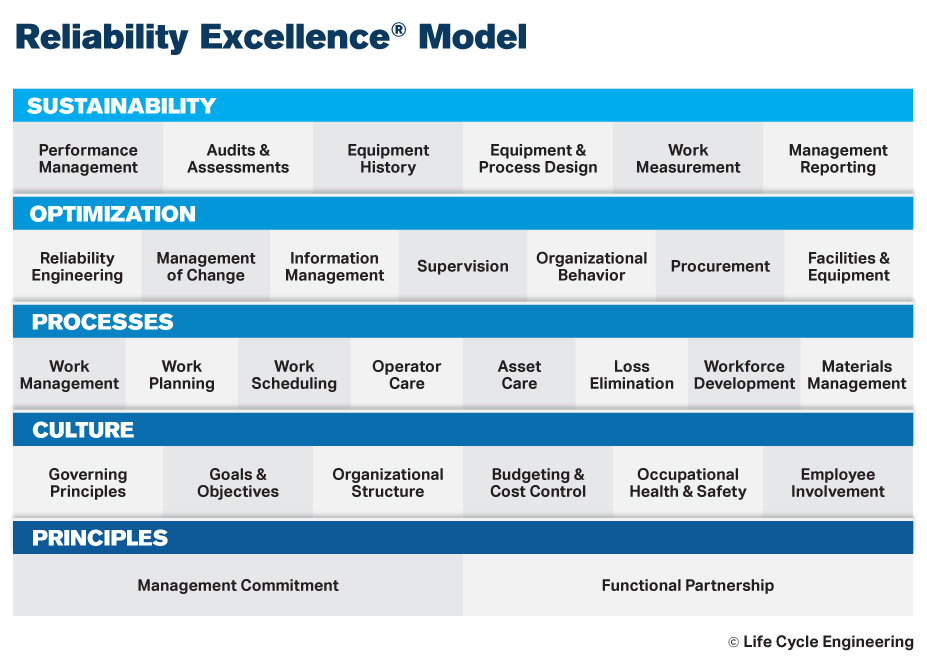

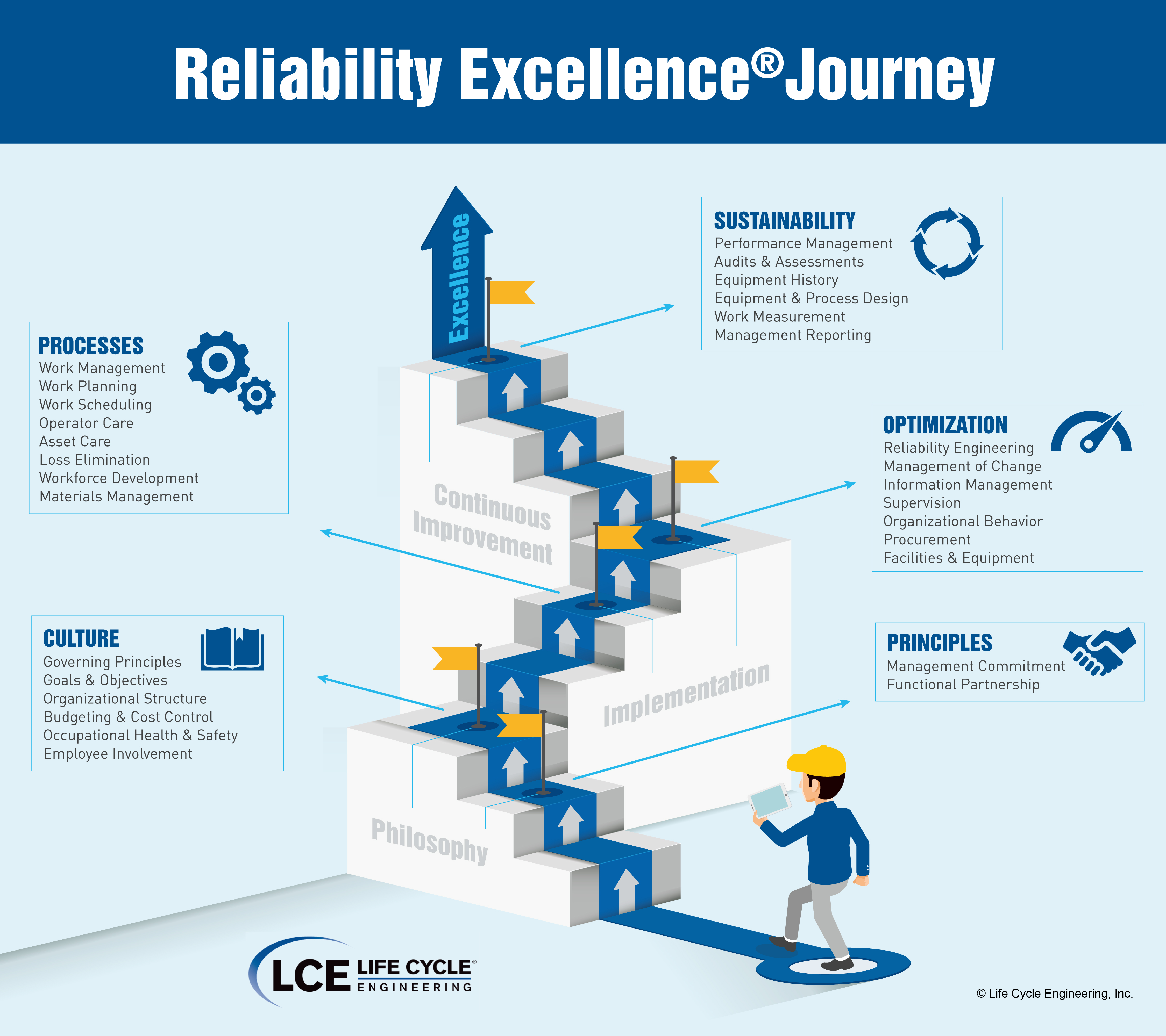

Reliability Excellence® Consulting

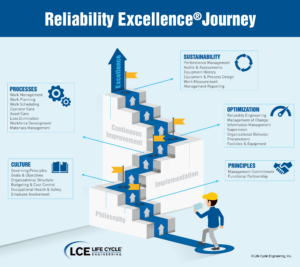

Reliability Excellence® (Rx) consulting, services and education drive improved asset and financial performance.

What to Expect:

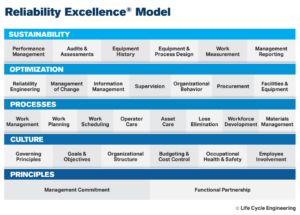

LCE’s Powered by Rx® approach creates reliability-centric standard practices for business processes, operational and maintenance work execution, asset reliability and organizational effectiveness.

- Improve the stability and consistency of key business and work processes

- Maximize the useful life and daily output of your physical assets

- Create a well-trained and engaged workforce that relentlessly pursues waste elimination

- Based on our proprietary Reliability Excellence® Model

Outcomes:

During consulting engagements, we target reliability and asset management services necessary to resolve specific, performance-limiting issues and integrate change management services vital to success.

We lead with education to support workforce development.

Typical business drivers that support developing a business case for implementing Reliability Excellence® include:

- Increased OEE / asset utilization

- Reduced labor, material and inventory costs

- Reduced maintenance costs

- Reduced production losses

- Improved safety and regulatory compliance

- Capital project avoidance

A Reliable Plant is a Safe Plant is a Cost Effective Plant

Meeting Increased Market Demand Through Reliability Excellence

Sustainable Work Practices Fuel Success for Food Manufacturer

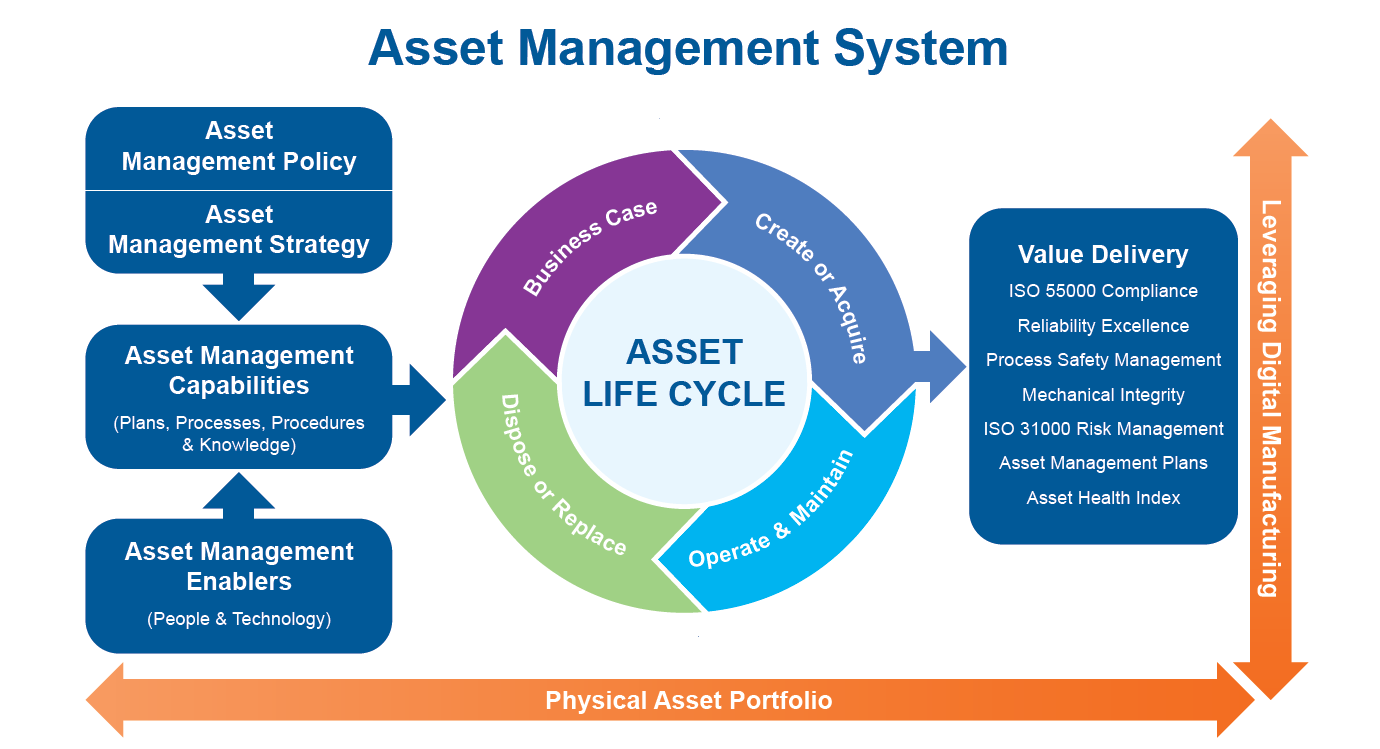

Life Cycle Asset Management

Physical asset management is foundational to the success of industrial and other asset-intensive organizations – and can be a source of competitive advantage.

An excellent asset management system optimizes costs, risk and performance across the entire asset life cycle.

What to Expect:

Using our proprietary tools, methods, and techniques, we can help you:

- Improve financial performance

- Operate safely and reliably

- Make informed asset investment decisions

- Integrate risk analysis into asset management decision-making

- Optimize risk-based maintenance strategies

- Optimize spending for maintaining assets

- Ensure your EAM /CMMS provides the right information

- Create a culture of continuous improvement, embraced by your skilled professionals

Outcomes:

Asset Management Systems and Capabilities — By using these nine work streams, LCE helps you develop the processes, procedures and knowledge required to best manage the asset life cycle:

- Leadership & Strategy

- Reliability Engineering

- Capital Delivery

- Design for Reliability

- Work Management

- Materials Management

- Operator-driven Reliability

- Shutdown, Turnaround and Outage Management

- EAM / CMMS

Success Story:

Chemical Processing Plant Uses Asset Management Best Practice to Build Total Process Reliability

ISO 55000 strategic planning and compliance preparation

Strategically managing physical assets across their life cycle ensures close alignment between asset management objectives and the organization’s long-term strategic plan.

What to Expect:

We offer a full range of services for companies interested in implementing ISO 55000:

- Gap assessments and scoring

- Implementation master plans

- Asset management capability development

- Asset performance framework models

Outcomes:

Using our proprietary tools, methods and techniques, we can help you build:

- Asset management policy

- Asset management objectives

- Asset management strategy

- Asset management plans

- Guidance for implementing an asset management system

Ten Things to Know About ISO 55000 The International Standard for Asset Management

Asset Management Plans an ISO 55000 Building Block

Operational Performance Assessments

Scalable and customizable diagnostics and assessments for benchmarking, establishing performance baselines, and discovering the root causes of underperforming areas or processes.

What to Expect:

Assessments identify and prioritize where improvements are most needed and most impactful. Our team can help you assess your organization’s:

- ISO 55000 / asset management system

- Reliability Excellence®

- Digital transformation / Industry 4.0 readiness

- Tactical, individual work stream performance

Outcomes:

Asset management capabilities assessment – effectiveness of more than 80 key processes across nine knowledge domains, integrating the key requirements of the ISO 55000 Asset Management standard.

Reliability Excellence® (Rx) assessment. Our proprietary assessment scores 29 performance centers linked to Principles, Culture, Processes, Optimization and Sustainability.

Tactical assessments – flexible and scalable for client-specific needs. We cover:

- Leadership and strategy

- Organizational change management

- Capital delivery / design for reliability

- Reliability engineering

- Operator-driven reliability

- Work management

- Materials management (MRO)

- Shutdowns, turnarounds and outages

- CMMS – SAP

- Facility condition

- Financial performance

- Condition-based maintenance / PM / PdM

Eight Steps to Include in Your Assessment Process

A Metallurgical Coke Producer Addresses Financial Challenges with Reliability Excellence

Operational Excellence Consulting

Develop an Operational Excellence program tailored to your organization’s specific goals and market challenges.

What to Expect:

Our operational excellence approach includes:

- Elevating the company culture

- Execution of and sustaining operational excellence projects

- Maintaining key priorities and focus

- End-to-end business transformation

- Keeping up with new technologies

- Leadership understanding and buy-in

LCE has helped hundreds of organizations achieve step-change improvement in performance with consulting, services, education, and staff augmentation.

Safety First Reliability Always Unmasking the Core of Operational Excellence an LCE Podcast

Lean Services and Performance Optimization

Our performance optimization services are designed as a comprehensive approach for solving chronic and persistent reliability issues with processes or manufacturing lines. Common reliability issues include production losses due to unplanned downtime, ineffective maintenance practices, lack of standardized processes, quality-related issues, and lost time due to material flow design.

What to Expect:

Clients using this targeted approach have increased OEE by an average of 5%. Depending on your specific cost / volume / profit equation, the improvement to the bottom line can quickly result in a positive ROI.

Implementation typically lasts from 6 to 12 weeks.

- Line Performance Optimization®

- Process Performance Optimization®

- EAM Optimization

- EAM Implementation

- EAM Assessment and Action Plan

- Enterprise Resource Planning IT Support

- SAP EAM Optimization

- Lean Manufacturing

Outcomes:

Performance optimization can include the following elements:

- Value stream maps focused on problem solving and identifying key loss elimination opportunities

- FMEAs on critical pieces of equipment

- Strategies to eliminate root cause

- Equipment Maintenance Plans to ensure sustainability

- Standardized best-practice processes for start-up, shut down and change over

- Visual management boards for the plant floor

- Tracked and managed production results

- Critical downtime causes are summarized using Pareto analysis

- The workforce is engaged in the problem-solving process for identifying corrective actions for addressing root cause

- We integrate change management throughout the process to fully engage the workforce and gain their active sponsorship and support for the changes in work processes, procedures and practices that are always a part of the solution. This change management component is essential to long-term, sustainable results

Best Practices for Using Value Stream Mapping as a Continuous Improvement Tool

Visual Management Boards What Are They and How Do You Use Them

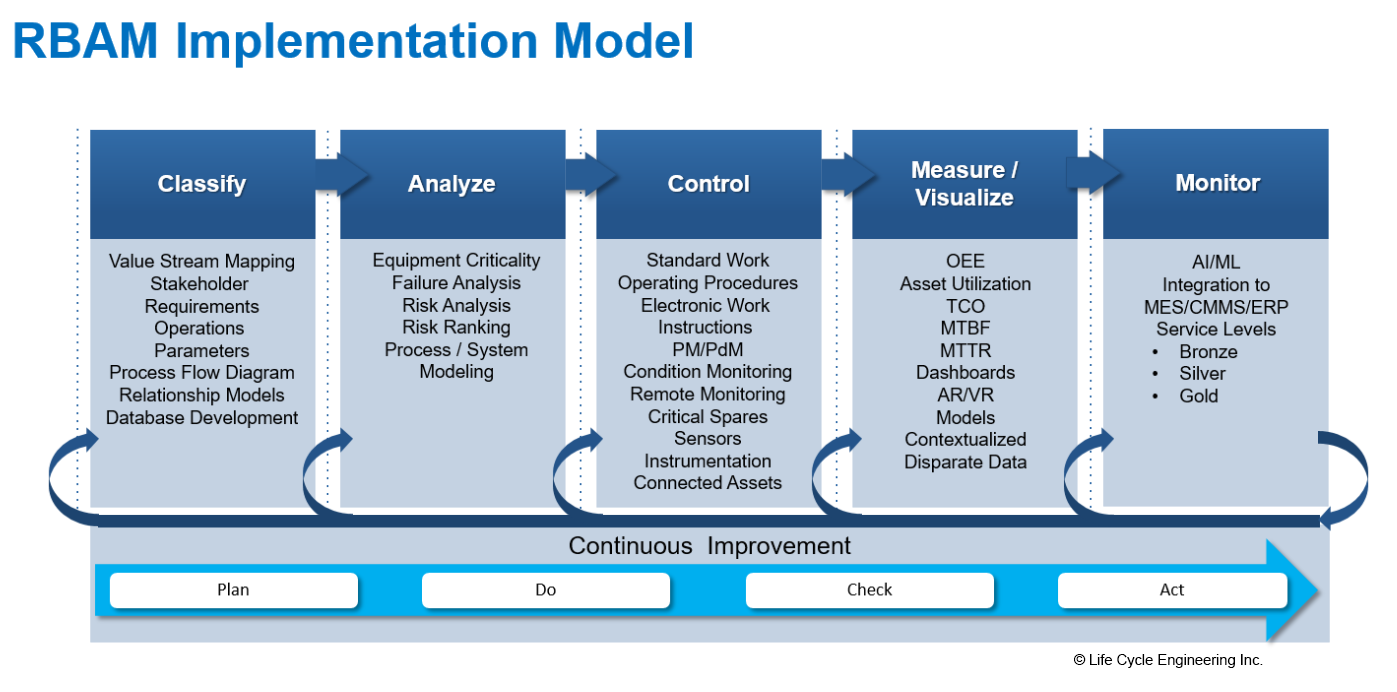

Reliability Engineering Support

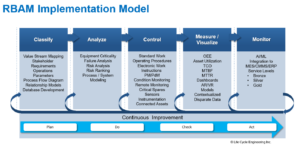

Reliability services to improve systems, develop asset maintenance strategies, and mitigate risks to extend asset life cycle and reduce total cost of ownership. We execute using core principles of Reliability Centered Maintenance, Risk-based Asset Management, Design for Reliability and Process Intelligence.

What to Expect:

Our reliability engineering services focus on identifying and managing asset condition and mitigating risks that could negatively affect the company’s value stream.

Three primary areas include loss elimination, risk management, and managing the life cycle of assets from design to decommissioning. These include:

- Help you appropriately prioritize how you spend time, money and materials fixing the most critical problems

- Provide the infrastructure for continuous improvement

- Help you meet your corporate business objectives, including regulatory compliance

Outcomes:

Using our Risk-Based Asset Management and other proprietary implementation models, Life Cycle Engineering will partner with you to build a risk-based asset management system that includes:

- Asset criticality development

- Design for Reliability

- Equipment Maintenance Plans and Job Plans

- Factory and Site Acceptance Testing

- Functional Specification Development

- Hierarchy Development

- Loss Elimination

- Preventive Maintenance Optimization

- Root Cause Failure Analysis (RCFA)

- Reliability-Centered Maintenance (RCM) Study

- Risk-Based Asset Management

The Swagelok Reliability Journey Includes an Important Role for Reliability Engineers

Developing Asset Management Plans

Asset Management Strategy Creating a Business Case for Change

Asset Performance Management (APM)

Our asset performance management services help organizations harness the power of data capture, integration, visualization and analytics to improve asset reliability, availability and impact overall performance.

What to Expect:

Asset performance management services like remote monitoring, predictive maintenance and predictive analytics help manage risk, minimize unplanned repair work, reduce equipment failure and extend asset life without unnecessary costs.

Our approach combines a managed deployment of predictive technologies and remote monitoring with standard risk-based asset management processes to add true reliability to your facility.

Services include:

- Program Design

- Program Assessment

- Program Deployment

- Program Management

- Monitoring and Analysis

Outcomes:

Using our partners and proprietary Risk-Based Asset Management processes to support:

- Assessing and identifying the most critical assets and systems to monitor

- Remote monitoring for critical assets

- Predicting asset failure and administering proper control strategy

- Creating risk-based asset maintenance and operation strategies

- Optimizing asset health and extending the asset life cycle

- Asset life cycle cost management

- Developing performance indicators to drive asset management program investments

Predictive Maintenance Program Self Assessment

Theres a Smarter Way to Approach the Labor Shortage

The Path to More Sustainable Operations is Paved With Technology But It Starts With People

Electronic Work Instructions

We help organizations quickly and affordably deploy and evaluate using augmented reality (AR) and electronic work instructions to help solve multiple problems affecting asset-intensive workplaces: a lack of skilled workers to execute work; a lack of easily accessible, documented work instructions; and ineffective technical training for complex work.

What to Expect:

Electronic work instruction development, deployment, and improvement to:

- Improve frontline worker productivity because it’s easier to complete tasks accurately and quickly

- Reduce rework and waste, boosting profit margins

- Improve training effectiveness, so employees can develop and use new skills faster, and labor productivity increases

Outcomes:

How does it work and what you can utilize:

- Support from an LCE Project Manager for administration, processes and projects

- On-site train-the-trainer workshops to address questions about system administration, job authoring and job execution

- Assistance in preparing initial equipment asset data

- Support in using the customer’s source content to create job plan templates

- A planning workshop for data transfer, solution roll-out and deployment

Next-Gen Mobility: Using Augmented Reality for Equipment Maintenance

LCE’s SEA Coaches Implementing Cutting-edge Technology in the Development of Sailor Training

Cybersecurity

Comprehensive information assurance / cybersecurity services, including HackWarz® and Red Hat training to help organizations educate their staff.

What to Expect:

LCE provides full-spectrum expertise in cybersecurity including:

- Risk Management Framework (RMF) / Assessment and Authorization (A&A)

- Platform IT (PIT) Systems Security

- Security Engineering

- Computer Network Defense (CND)

- Vulnerability Analysis and Threat Hunting

- Incident Response

- Cloud Migration

- Software Development

- DevSecOps

- COTS/GOTS Integration and Sustainment

- Data Management and Administration

- Network Infrastructure Administration

- Cybersecurity Training and Certification

- HackWarz®

- Red Hat

Outcomes:

LCE team members have the skills and experience to create and maintain system security at any point in the software creation process, helping to keep your organization’s systems and information secure.

We tailor our role to your organization’s needs, including IT development and operations and maintenance, cyber operations, training and program management.

In our HackWarz® events, participants review the Risk Management Framework (RMF) six-step process (NIST 800-37) and use the RMF methodology to outline a defense-in-depth strategy. This includes correlating STIGs and IA controls to the new RMF controls. Participants will execute “white hat” attacks against typical IT systems in the hands-on, Hack Warz lab environment. Hack Warz® is set up as a capture-the-flag event in which participants gain exposure to hacker tools and common exploits. After the lab, participants will debrief and use the RMF methodology to update their defense-in-depth strategies.

We offer Red Hat certification exams at our corporate headquarters.

To learn more, download a brochure or contact one of our experts with your questions.

Hackwarz Fueling Innovation and Expertise in the Cybersecurity Arena

What’s your vision for a smart operation?

Our approach leverages more than 40 years of multi-industrial experience and combines reliability consulting, engineering services, education and change management to achieve consistent step-change performance improvement. Our industry expertise, unique methodologies and comprehensive educational offerings have made LCE a leading provider of reliability services worldwide.

What does better look like?

- Increasing throughput

- Creating a sustainable cost structure

- Increasing efficiency

- Complying with regulatory change

- Adapting to change

- Building safer work environments

How We Do It

We use a “diagnose before prescribing” philosophy to match solutions to our clients’ needs, including transformations based upon our Asset Management Framework (ISO 55000), Risk-Based Asset Management and Reliability Excellence Models and targeted reliability and asset management services necessary to resolve both strategic and/or specific tactical issues. We lead with change management and training services vital to the success and sustainability of most initiatives.