- Commercial

Commercial Services

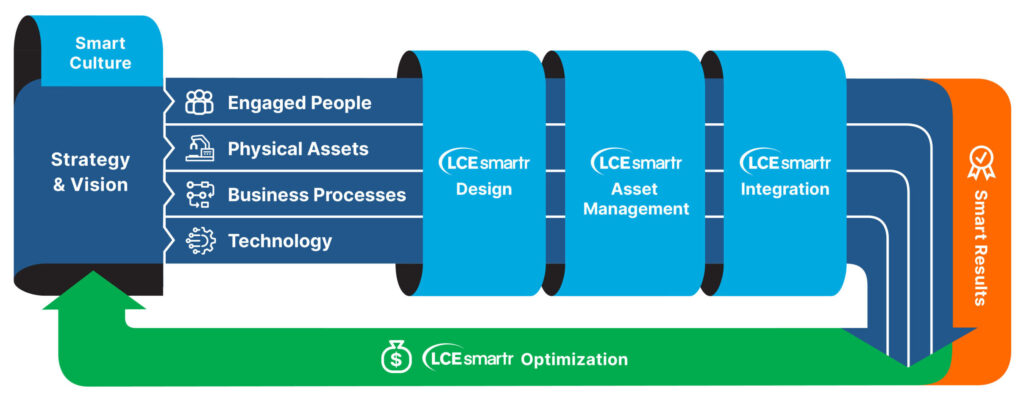

No matter how smart your equipment, it’s nothing without the people who make it work. That’s where LCEsmartr comes in. Let us help you build the smart culture needed to enable smart operations.

Play Video

Automotive & Manufacturing ♦ Chemicals ♦

Consumer Packaged Goods ♦ Energy & Utilities ♦ Food & Beverage ♦ Life Sciences ♦ Oil & Gas ♦ Metals ♦ Mining ♦ TransportationLet’s Talk

- Federal

Federal Services

Each member of our team brings deep experience from the field and a mindset to help. And when you choose LCE, our people become your people. Your Mission. Accomplished.

Play Video

Cybersecurity and IT Solutions

Integrated Logistics Support

Marine Engineering

Training and Workforce

Development

Waterfront Fleet

MaintenanceLet’s Talk

- Institute

Life Cycle Institute

Learn about asset management, root cause analysis, planning and other reliability topics from experts who truly care about solving difficult problems, supporting people’s development, and helping you achieve the best outcomes. Register now.

Play Video

Have a question?

- Resources

Resources

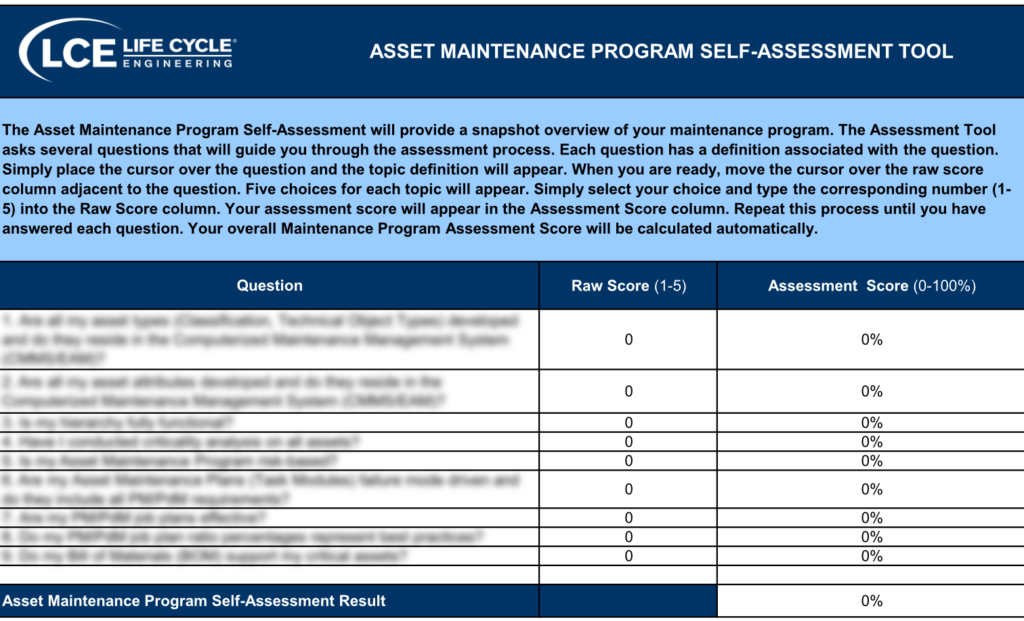

Our learnings. Your resources. The #1 ranked section of our website. Why? It’s all the tools, resources and guides you need. Dig in.

- About

About

Success only happens when we see it in others. We wake up every day to put our collective experience, skills and talents to work for the success of your operation. Learn more.

Play Video

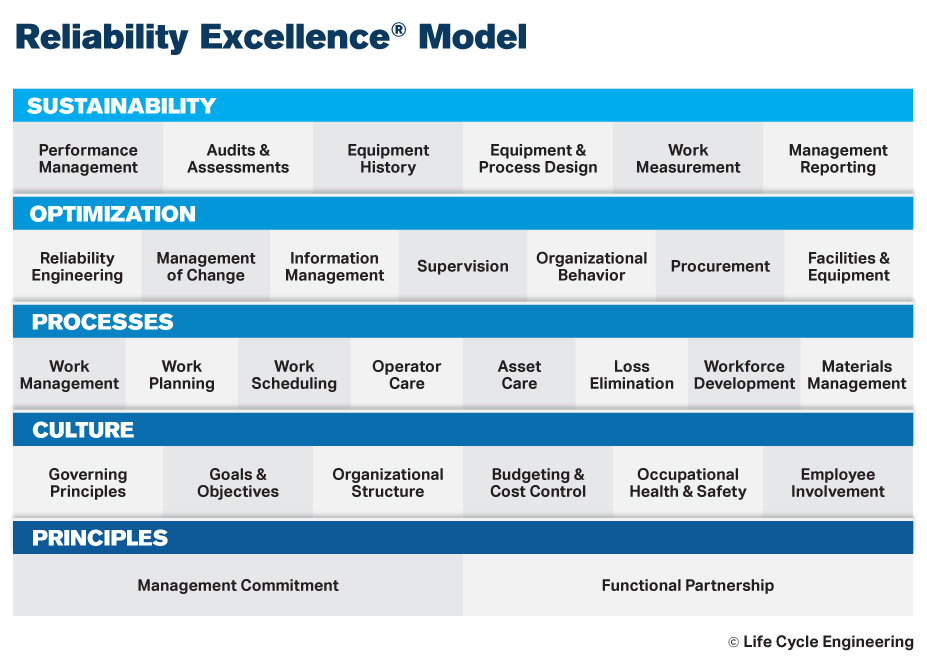

We help organizations and teams with asset-intensive operations improve operational effectiveness in private industry, public entities, government organizations and the military. Since 1976, LCE has successfully implemented engineering, asset management, reliability, maintenance and information technology solutions worldwide by combining a staff of industry experts, unique and proven processes, and comprehensive education courses. Learn more about our Solutions & Services.

We get up in the morning to use our collective skills and experience to help each other and our clients achieve their full potential.

In every aspect of our business our actions always drive people and organizations to achieve their long-term performance capability (not solely their short-term profit or cost-cutting targets).

We serve a variety of markets from private and public asset-intensive manufacturing plants and facilities to the U.S. Department of Defense, including all branches of the military and other federal agencies. To learn more about some of the challenges we help our clients solve, please visit our Customer Success section.

Let’s Talk

- Careers

Careers

See yourself at LCE. We’re committed to helping you see personal success as you help your colleagues and clients achieve it, too.

Your career success. Our mission.

Let’s Talk