Start with people. Build a culture of change. Leverage technology as an accelerator.

It’s never been more exciting (or challenging) to be in a business where equipment performance directly impacts business performance. Technology is creating opportunity in just about every corner of the plant.

Yet only 30% of manufacturers are meeting their digital transformation goals. Why? Because as much as we’d like a silver bullet, there isn’t one. Technology is an accelerator, not a fixer. Without the fundamental practices in place, technology will only speed up the path to failure and make small problems worse.

Digital transformation starts with a cultural transformation. There is no way around it. Align people, business processes, and technology with your physical assets to build a smart culture – and you can have a smart operation.

Are your employees suffering from “factory blindness”?

If you’re seeing…

- Resistance to change

- An increase in avoidable accidents or mishaps

- Growing inefficiencies

- Workers on autopilot

…your operation’s got a case of factory blindness. Don’t try to make a change to your equipment, processes or technology without addressing it. You need to overcome complacency and get buy-in before your transformation can succeed.

Smart operations start with smart cultures

Industry 4.0 is turning traditional equipment into “smart machines,” transforming physical assets across industrial and manufacturing environments. This gives us an unprecedented understanding of how plants are functioning, one machine – and all the machines – at a time, over time.

This is an incredible opportunity – to manage plants differently. Where the ‘equipment’ was once seen as a costly expense, it’s now the engine of performance, productivity and safety. These assets are the future; your competitive advantage, fueling profitability and sustainability.

Is it really that simple? Connected machines. Unlimited data. Technology making everything run better. Sounds just a bit too good to be true, doesn’t it? That’s because it is. The promise is real AND far from reality for most companies today. Why? Because no matter how much we want to reduce this problem to data, technology, and equipment, it’s about people and processes.

It’s about how we organize ourselves to take advantage of the massive opportunity connected technology affords us. It’s the system we create – our people, the way we work, our equipment and technology – to realize the opportunity.

This is the hard stuff – getting people to adopt new ways of thinking and behaving – especially if they’re comfortable with the status quo. And it’s not just enough to get leadership bought in; your frontline workers need to be on board too.

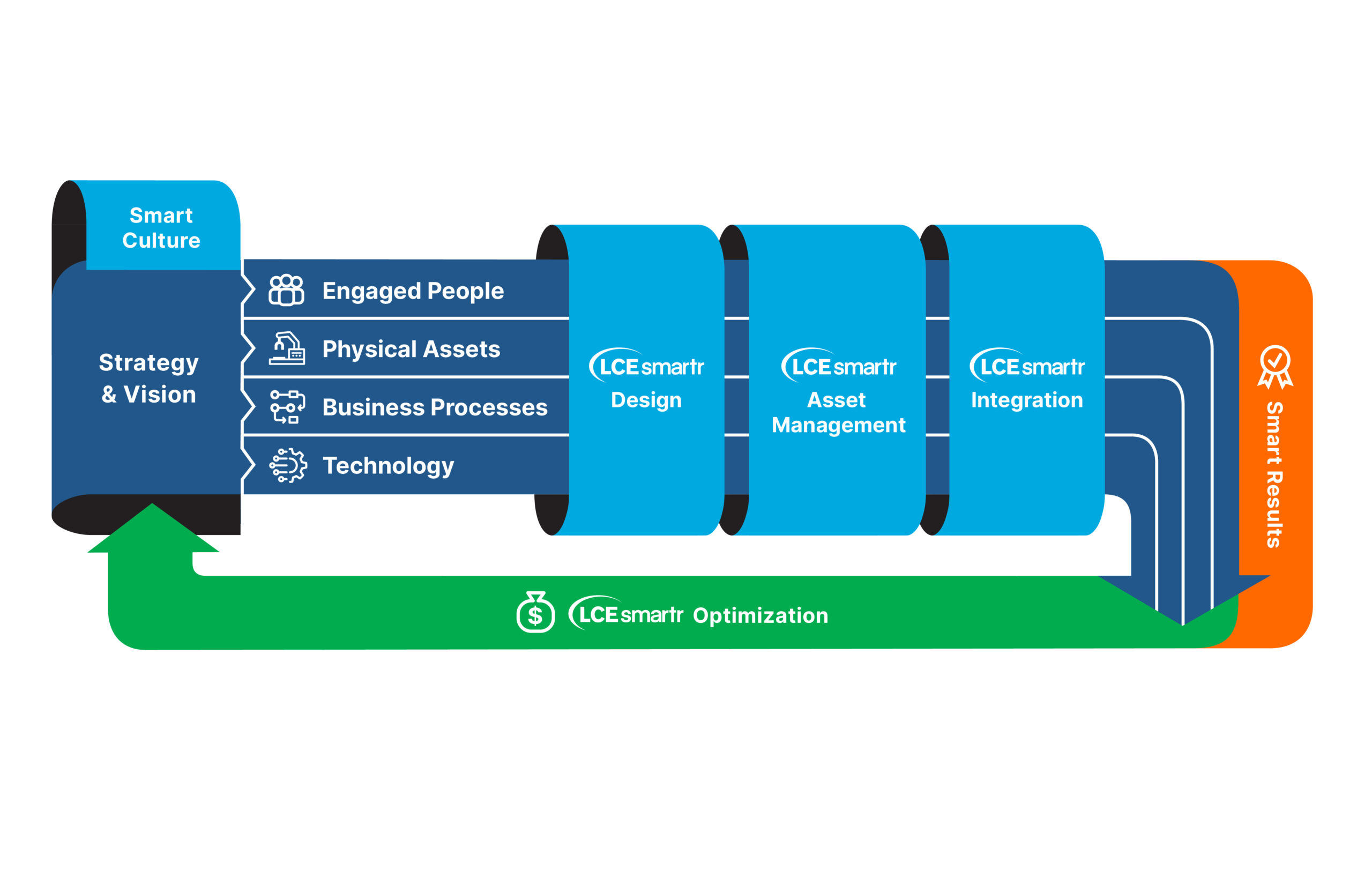

The Path to Smart Culture Model

Smart cultures consider the whole picture of your company’s operations. The journey starts where you are: with your goals and what you’re willing to invest to get there. LCEsmartr services can help you determine your strategy and vision and generate engagement across your organization. Then, you’re in a position to transform your system. We can help you organize your operation – align the people, culture and mindset, business processes, tools and physical assets – to capture this opportunity.

And once you start your transformation, you’ll continue to identify opportunities to take your operation to the next level, and continue to iterate. You’ll be well on your way to joining that exclusive “Industry 4.0 success” club!

________________

For more than four decades, LCE has helped organizations large and small, public and private, local and global, transform how they think, understand and manage the life cycle of their assets to meet business goals. Industries evolved, people innovated, and technology transformed, but the fundamentals stayed the same.

We help organizations transform their asset management approach and we’ve built the gold standard resource to accelerate the process.

Ready to learn more? Let’s talk!