The Keys to an ISO 55000-Compliant System

Overview of an Asset Management System

The discipline of physical asset management is rapidly evolving as companies rush to understand the implications of the ISO 55000 Asset Management Standard. Each business has its own particular reasons, but they tend to all arrive at the same question: will the commitment to establishing an asset management system provide a sustainable competitive advantage? If businesses use an asset management system to optimize cost, risk and performance across the asset lifecycle, will they achieve the necessary value from their assets?

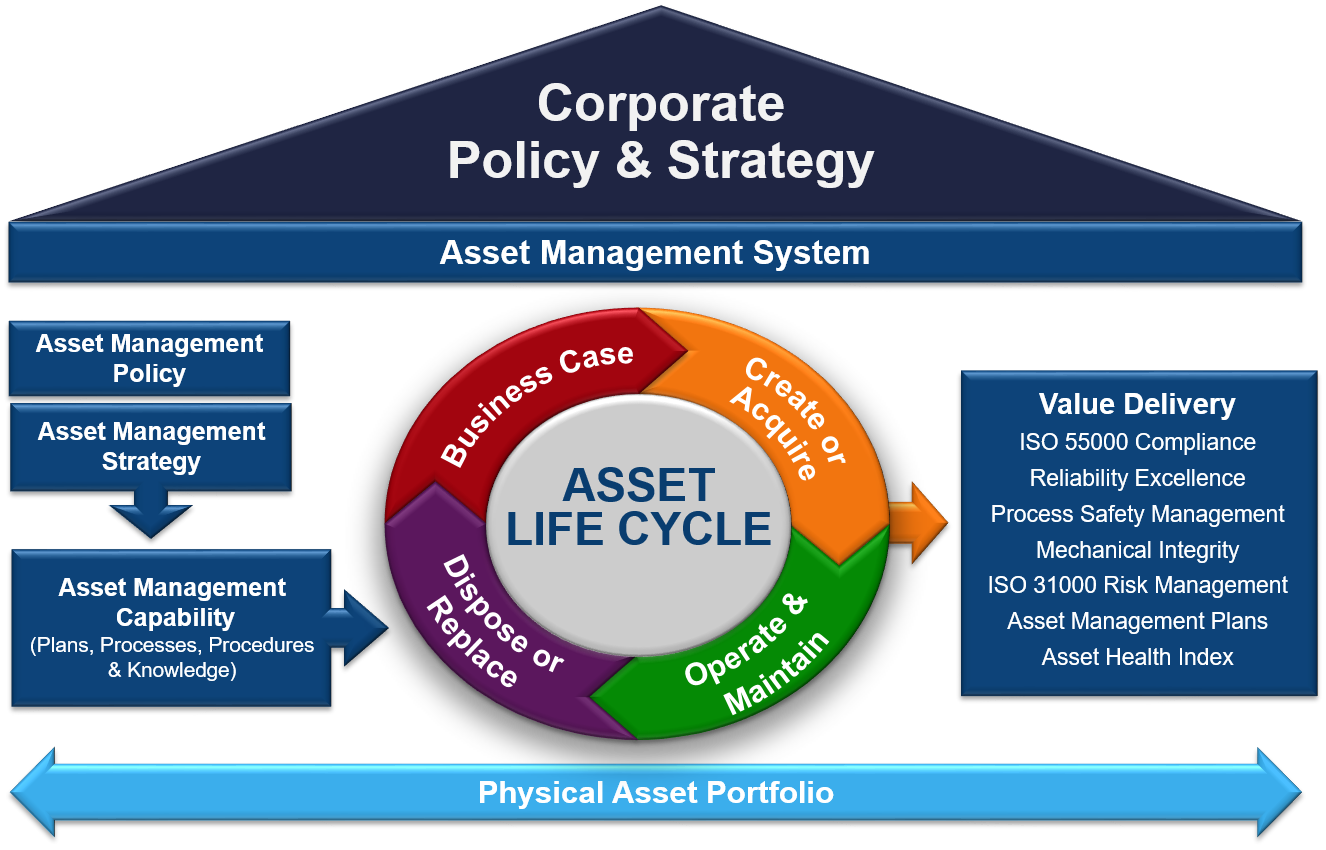

To evaluate whether implementing a system is worth it, it’s necessary to understand an asset management system’s key components. LCE’s Asset Management System Framework (Figure 1) establishes the critical linkages between the elements of an asset management system and the value that the system can produce. From an ISO 55000 perspective, leadership, policy and strategy are overarching elements necessary for establishing the organization’s commitment to an effective asset management system. These elements define governing principles and describe how asset management will contribute to meeting organizational goals and objectives.

Figure 1. Integrated Framework for the Asset Management System

The ISO 55000 standard focuses thoroughly on what is required. However, the standard does not prescribe the how. This lack of clarity on how to implement an asset management system leaves many questions unanswered. Fortunately, there are resources available that can guide companies through the implementation process. Within the LCE Asset Management System Framework the crucial guidance on “how” is contained within the Asset Management Capability block. It is this critical step that defines the plans, processes, procedures and organizational knowledge that are foundational to creating an asset management system.

The Phases of the Asset Life Cycle

The ISO 55000 Asset Management Standard clearly establishes the expectation that assets will be managed throughout their lifecycle. LCE’s Asset Management System Framework integrates the Asset Management Capabilities processes, procedures and knowledge into the asset lifecycle stages. The LCE implementation methodology comprises more than 90 key processes and eight critical knowledge domains that are associated with each individual lifecycle phase.

Identifying knowledge domains associated with key processes and procedures provide additional clarity to the asset management capability system view and can be easily mapped back to the asset lifecycle phases. In addition, the knowledge domains facilitate an organizational view of the processes and procedures, making it easier for companies to organize and deploy implementation activities. The key knowledge domains are:

- Leadership & Change

- Capital Delivery

- Reliability Engineering

- Work Management

- Materials Management/Supply Chain

- Operator Care

- Shutdown, Turnaround and Outage Management

- eAMS/CMMS

When fully implemented, the resulting asset management capabilities define a best-in-class asset management system designed to achieve maximum, risk-based value from your physical asset portfolio.

Asset Management Capabilities

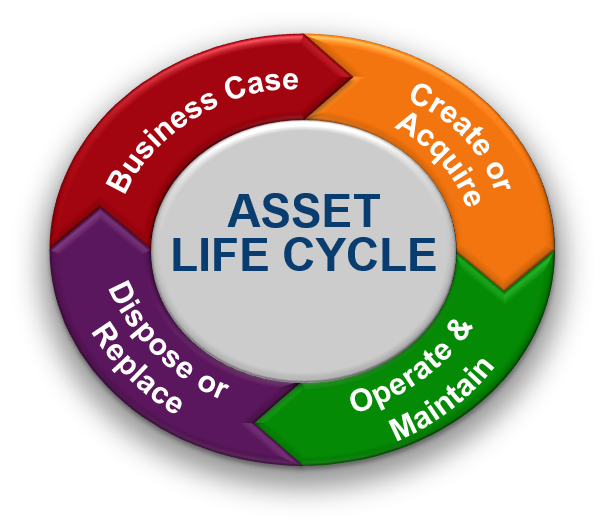

Asset Management Capabilities can be mapped to the four phases of the asset life cycle, as described below. This mapping will provide a basic understanding of the key processes and procedures that are associated with each of the phases and should highlight any gaps that may exist.

Definition: The Business Case phase produces the business case, the single most important document in helping an organization’s leadership evaluate the return on physical asset investments. It defines the problem statement, the stakeholder requirements and the resulting business opportunity if solved. The business case is more than just financial justification.

Definition: The Business Case phase produces the business case, the single most important document in helping an organization’s leadership evaluate the return on physical asset investments. It defines the problem statement, the stakeholder requirements and the resulting business opportunity if solved. The business case is more than just financial justification.

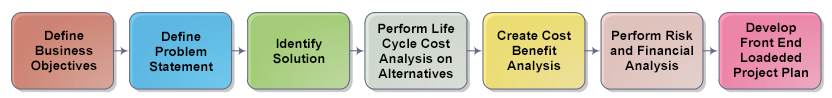

Process: The key processes associated with the business case phase include strategic planning, capital planning and evaluation, lifecycle cost analysis, and auditing. Figure 2 below depicts a generic business case development process for investing in physical assets. Note that the process begins with defining asset management objectives and concludes with a hand-off to a project management process. These processes must also connect to the asset management objectives and select activities within the asset management plans.

Figure 2. Business Case Development Process

Tools: The primary tools center on forecasting and analysis. Most businesses rely on spreadsheet-based applications that are often supported with some level of electronic workflow for approval and post-audit activities. Other critical tools support the risk assessment and planning that are necessary for developing a risk management plan that is a key component within the asset management plan.

Definition: The Create or Acquire phase of the life cycle is where the decisions made have the greatest impact on the total cost of ownership of an acquired or created asset. This is also where the greatest collaboration of a cross-functional team is needed to ensure that intended benefits will be realized. Detailed engineering through commissioning occurs in this phase.

Definition: The Create or Acquire phase of the life cycle is where the decisions made have the greatest impact on the total cost of ownership of an acquired or created asset. This is also where the greatest collaboration of a cross-functional team is needed to ensure that intended benefits will be realized. Detailed engineering through commissioning occurs in this phase.

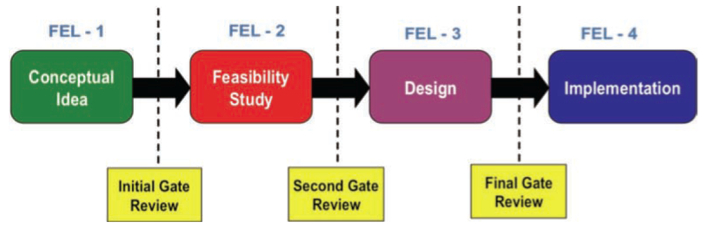

Process: The front-end-loading process is the transition from the business case to the Create or Acquire phase as depicted in Figure 3. This process contains the activities that ensure the business objectives in the business case are realized throughout the asset life cycle.

Figure 3. Front End Loading

Important deliverables pass from stage to stage as the process moves the acquired or created asset from an idea onto the shop floor.

- Conceptual Idea: Determine the background and objectives, such as interaction with other goals, and procedures and plans.

- Feasibility Study: This study should outline the planning period, stakeholder interest, accountability and responsibilities for asset management, and details of asset management systems and processes.

- Functional Design: The functional design stage includes a description of asset configuration, identification of assets by category, justification for assets, proposed levels of service, customer-oriented performance targets, other asset performance targets, and justification for target levels of service.

- Implementation: The implementation stage puts the project plan in motion, including resources, milestones and budgetary constraints, asset age and condition. Additionally, there should be a focus on detailed infrastructure performance measures.

Tools: Some of the tools used during this phase include process flow diagrams, RAM analysis, failure mode and effects analysis, risk and failure analysis and project management and tracking.

Definition: The Operate & Maintain phase is where value is created. The newly commissioned assets function to provide the solution defined in the business case. This is also the longest phase by the duration of the asset life cycle. Once this phase of the life cycle is reached, only about 15% of the total cost of ownership can be influenced without recapitalization of the asset.

Definition: The Operate & Maintain phase is where value is created. The newly commissioned assets function to provide the solution defined in the business case. This is also the longest phase by the duration of the asset life cycle. Once this phase of the life cycle is reached, only about 15% of the total cost of ownership can be influenced without recapitalization of the asset.

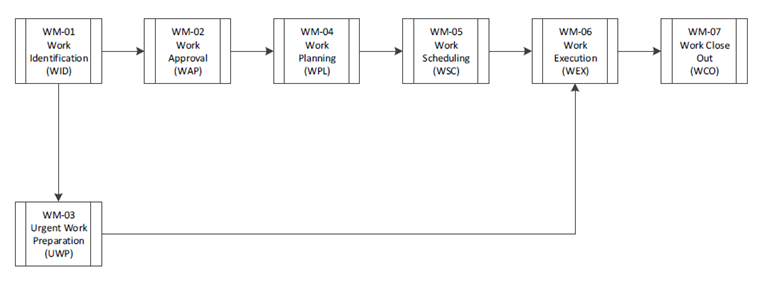

Process: Since this phase is predominantly performance evaluation and improvement, the major focus is on evaluating the effectiveness of the controls to mitigate or eliminate predominant failure modes and identifying waste within the value stream. The work management process, as depicted in Figure 4, and reliability knowledge domains and associated processes are integrated to ensure planned work is evaluated for accuracy and unplanned work is evaluated to identify new predominant failure modes and effectiveness of current controls.

Figure 4. Work Management Process

Tools: Since this phase of the life cycle is focused on the assets meeting their function, the tools used are focused on continuous improvement. Value stream mapping, visual management, and kaizens are all lean tools focused on eliminating waste. Within the realm of reliability engineering, there are root cause analysis tools such as cause and effect, fault tree, sequence of events, and event-causal factors. There are also audit and surveillance tools to evaluate the effectiveness of work management, operations, material management and reliability engineering. Performance evaluation relies on various metrics and key performance indicators to drive improvement.

Definition: The Dispose or Replace phase occurs when the disposal, decommissioning, or replacement of an asset is necessary following the end of an asset’s service life or change in asset requirements due to rationalization. If unplanned, this phase can have a significant negative impact on an organization’s financial statement.

Definition: The Dispose or Replace phase occurs when the disposal, decommissioning, or replacement of an asset is necessary following the end of an asset’s service life or change in asset requirements due to rationalization. If unplanned, this phase can have a significant negative impact on an organization’s financial statement.

Process: By breaking down the total scope into manageable pieces, activities, timelines, and resources can be developed to structure the disposal or replacement project. The same program management tools used during the Acquire or Create phase apply in this phase, along with the specific components identified in the business case. Therefore the processes are the same, just in reverse.

Tools: As with the processes, the tools would be the same.

Conclusions

Companies considering the strategic decision to implement an asset management system as defined by the ISO 55000 Asset Management Standard will undoubtedly have many questions. The most significant question is how to define and design the system. The standard refers to the need for operational planning and control processes without providing further insight into how to define and implement such processes.

To help companies understand these requirements the Life Cycle Engineering Asset Management System Framework provides an excellent model for understanding the critical system design elements. The Asset Management Capabilities block represents over 90 processes and procedures that, taken together, define the foundation of an asset management system. These processes and procedures are defined within knowledge domains and applied across the asset lifecycle. With over 30 years of implementation experience, LCE continues to help businesses develop their own asset management systems designed to achieve maximum value from their physical asset portfolio.

© Life Cycle Engineering, Inc.